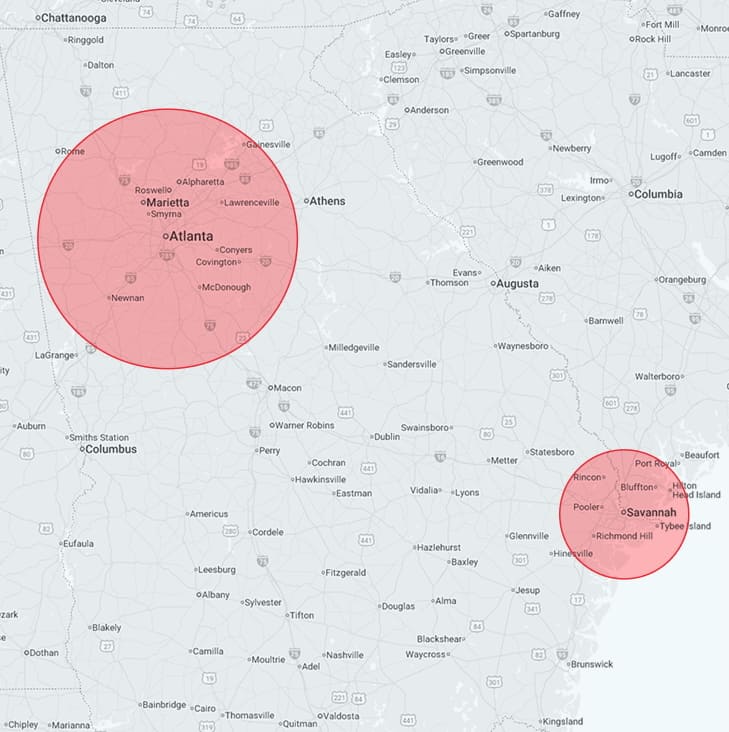

Serving Greater Atlanta & Savannah/Hilton Head

HVAC, Plumbing & Electrical Experts

Our Services

Air Conditioning

Heating

Plumbing

Electrical

Weatherization

Commercial

50+ Years Serving Property Owners in the Atlanta Metro Area

At R.S. Andrews, our HVAC technicians are committed to protecting your indoor comfort with top-notch heating, cooling, plumbing, and electrical solutions in Atlanta and the surrounding areas. From 24/7 emergency repair services to AC maintenance to heating installation, our experts have over 50 years of experience to keep your home or business running comfortably and reliably in the Atlanta Metro Area.

Since 1968, our fully insured team has provided a variety of professional services tailored to your residential and commercial needs.

A Few Reasons To Smile

Ready for Emergencies

Decades of Experience

Financing That Works For You

Satisfaction Guaranteed

Current Special Offers

Expires: Jan 31, 2026

Expires: Jan 31, 2026

Expires: Jan 31, 2026

The Smiley Advantage Plan

Save Money

- Up to 10% off service repairs

- Diagnostic reduced to $79

- Twice annual system maintenance with duct inspection included

- Each additional unit $9.99/month

- Special club member benefits for HVAC, plumbing, and electrical service

- Exclusive discounts on emergency services

Save Time

- VIP Service

- Priority Scheduling

- We take care of calling you – you don’t have to remember to call us to schedule your tune up!

- Special Services

- Free HVAC Replacement Consultation

Peace of Mind

- Keeps your family safe and comfortable all year round

- 100% Satisfaction Guaranteed

- Save Money on Your Utility Bills

- Keeps Your Systems in Peak Operating Condition

- Reduces Breakdowns

Reach Out To Us

For over five decades, R.S. Andrews has delivered trusted HVAC, plumbing, and electrical services to homes and businesses across the Atlanta Metro Area. Our fully insured team is available 24/7, bringing fast, professional solutions to restore comfort, safety, and convenience when it matters most.

We combine deep industry experience with up-front pricing, flexible financing, and a commitment to customer care that’s earned generations of local trust. Whether you need seasonal maintenance, a system upgrade, or urgent repairs, you’ll get dependable service backed by lasting results. Reach out today and experience the service Atlanta has counted on since 1968.

Awards & Our Affiliations

Proudly Serving Greater Atlanta & Savannah/Hilton Head

We are happy to serve the Greater Atlanta & Savannah/Hilton Head areas, including these communities: Acworth

Acworth Alpharetta

Alpharetta Austell

Austell Avondale Estates

Avondale Estates Brookhaven

Brookhaven Buford

Buford Canton

Canton Chamblee

Chamblee Clarkston

Clarkston Conyers

Conyers Cumming

Cumming Dacula

Dacula

Heater on the fritz? Frustrated with plumbing problems? R.S. Andrews is just a call away!