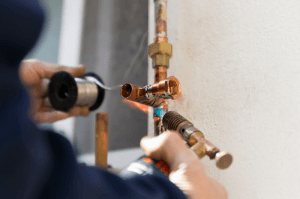

In plumbing projects, joining copper pipes need a reliable method to ensure leak-free connections that resist time and pressure. Without proper techniques, pipes can leak, corrode, or even fail. This may lead to costly repairs and water damage.

Copper pipe soldering is the process of joining copper piping and fittings together using molten metal to create a watertight and durable seal. Copper pipe soldering offers durability, corrosion resistance, and flexibility in various plumbing scenarios. It’s commonly needed for both minor repairs and new installations where a reliable connection is needed.

In this guide, we will walk you through the basics of copper pipe soldering. Let’s explore how copper pipe soldering ensures your plumbing system stays leak-free and efficient.

What Is Copper Pipe Soldering?

Copper pipe soldering is a fundamental skill for anyone looking to do basic plumbing repairs or installations at home. It involves joining copper pipes together by melting a filler metal, known as solder, into the joint between them. The result is a watertight seal that ensures your plumbing system remains efficient and leak-free.

How Does Copper Pipe Soldering Work?

Whether you’re fixing a leaky pipe or setting up a new plumbing system, knowing how copper pipe soldering works is important. Below are some of the principles of this process to give you a clear picture of how it gets the job done.

1. Apply Heat to the Copper Pipe Joint

The soldering process begins by applying heat to the copper pipe joint. This is typically done using a propane torch. The key is to heat the joint evenly so that the solder will flow correctly around the entire circumference of the pipe.

The temperature must be high enough to melt the solder but not so high that it damages the pipe.

2. Apply Solder to the Joint

Once the joint is adequately heated, the next step is to apply the solder. Solder is a metal alloy, usually a combination of tin and lead (although lead-free versions are now more common due to health concerns).

When the joint is hot enough, touching the solder to the pipe will cause it to melt and flow into the gap between the pipe and the fitting by capillary action.

3. Sand the Copper and Apply Flux

For the solder to form a strong bond, the copper must be clean and free of any oxidation. This is because it can prevent the solder from adhering properly. This is why a cleaning step is important before heating.

This typically involves sanding the copper and applying a flux. Flux is a chemical cleaning agent that helps remove any residual oxides and promotes the adhesion of the solder to the copper.

After the solder cools and solidifies, it forms a strong, watertight seal that should last for many years with proper installation. The success of soldering depends on preparing the copper properly and applying the right amount of heat and solder during the process.

Advantages of Copper Pipe Soldering

Copper pipe soldering offers several benefits that make it a preferred method for plumbing installations and repairs. Some of the advantages are the following:

Durability

One of the most significant advantages of soldering copper pipes is the durability of the joints. Once soldered, the connections are extremely strong and can last decades without leaking. This long lifespan makes copper pipe soldering a cost-effective choice over time.

Leak-Proof Seals

Soldering creates a watertight seal that prevents leaks. The solder fills any gaps between the pipe and the fitting, ensuring that no water can escape. This is important for maintaining the integrity of a home’s plumbing system and preventing water damage.

Cost-Effectiveness

Compared to other joining methods like brazing or using press fittings, soldering is generally more affordable. The tools and materials needed for soldering, such as a torch, solder, and flux, are relatively inexpensive and widely available.

Versatility

Soldering is versatile and can be used in various plumbing applications. Whether it’s for water pipes, heating systems, or gas lines (using appropriate solder and techniques for gas), soldering is adaptable to many types of installations.

Disadvantages of Copper Pipe Soldering

While copper pipe soldering is a popular method for joining pipes, it does have some drawbacks that are important to consider:

Requires Heat Application

The need to use a torch for soldering can be a disadvantage in situations where open flames are a safety risk. In confined spaces or near flammable materials, the heat from the torch can pose a significant hazard.

Skill and Precision Needed

Although soldering can be learned by most DIY enthusiasts, it does require a certain level of skill and precision. Inadequate preparation or incorrect technique can lead to weak joints or leaks. This might need repairs or even complete redoing of the soldering work.

Potential for Heat Damage

The intense heat applied during soldering can sometimes damage the pipe or surrounding materials if not handled carefully. This is particularly relevant in areas where pipes are close to sensitive structural elements or other installations.

When Do You Need Copper Pipe Soldering?

Knowing when to use copper pipe soldering can save you time and hassle when tackling plumbing projects. It is helpful in the following scenarios:

Installing New Plumbing

Soldering is typically required when installing new copper plumbing systems or extending existing ones. It provides a secure, lasting join that is important for the system’s integrity.

Plumbing Repairs

For repairs that involve replacing sections of copper pipe or fixing leaks, soldering is often the method of choice. It ensures that the repair blends seamlessly with the rest of the plumbing.

Remodeling Projects

Soldering new connections during remodeling projects that involve moving or altering plumbing fixtures ensures that the modified system functions properly without leaks.

Upgrading Systems

When upgrading plumbing systems to handle higher pressures or temperatures, soldering new fittings and pipes provides the necessary durability and performance.

Overall, this expertise is particularly important when choosing the right copper pipe fittings, ensuring copper pipe joint sealing, and undertaking copper pipe repiping projects. By honing your soldering abilities, you can achieve reliable, long-lasting results in all your plumbing endeavors.